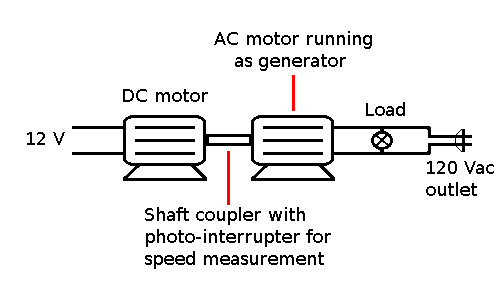

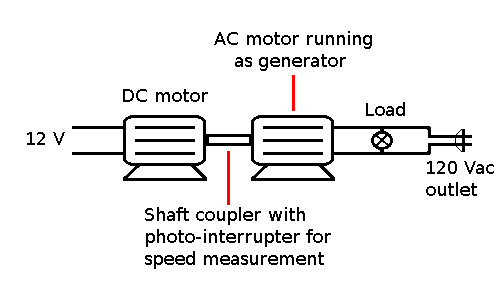

This page details my experiments with asynchronous motors (induction motors, squirrel-cage motors) in generator mode. As you may know, regular induction (asynchronous) motor will also work as generator, if rotated somewhat faster above its rated synchronous speed and provided with some reactive power (magnetizing current). Synchronous speed in RPM (rotations per minute) is equal to 3600/pairs of poles (North America, 60 Hz AC lines) or 3000/pairs of poles (Europe and elsewhere, 50 Hz AC lines). Typical rated motor speeds for motors with two pole pairs (four poles) are around 1750 RPM in North America and around 1450 RPM in Europe. For example, if motor rated speed is 1740 RPM, if you spin it at 1860 RPM it will generate power equal to its nameplate motor rating. For this to work, reactive power must be provided to the motor. If it is connected to the electrical grid, reactive power is drawn from there. If it is operating as standalone generator, reactive power is provided by capacitor connected between the motor terminals. Normal induction motor operates on simple principles. Stator receives current from the grid, and induces currents in short circuited rotor squirrel cage. Opposite magnetic polarity is created in rotor with respect to stator, and rotor is dragged along behind stator magnetic field. In motor operation, rotor always turns slower than stator field (slower than synchronous speed) by amount known as slip. If rotor would turn at the same speed as stator field lines, no voltage would be induced in rotor because no stator magnetic field lines are cut. Rotor would have no circulating current, and motor would consequently produce no torque. In generator operation, rotor is turned by external prime mover above the synchronous speed. Since rotor is now cutting the stator field lines, current is again induced in rotor. This current creates magnetic field, which now cuts stator magnetic field lines. Additional active current is now created in stator coils, and active power is produced. From brief explanation above, we can see that induction motor will require magnetizing current (reactive power) in both modes of operation: motor or generator. In addition, active current will be taken from the grid for motor operation, but will be returned to the grid during generator operation. We will first examine small asynchronous (squirrel-cage) motor as an AC generator with direct connection to alternating current grid. Test setup connections:

Purpose of this test was to examine the behaviour of a small fractional horsepower squirrel-cage motor when used as a generator of alternating current, connected to AC electric grid. It was found that AC generation is possible even with small and inefficient 0.05 horsepower motor used. Motor was connected to the electrical grid in this experiment, magnetizing current (reactive power) being provided from the grid.

DC motor was used to drive the AC asynchronous (squirrel-cage/induction) motor. When speed above 1800 RPM was reached (4 pole motor, 60 Hz), AC motor was connected to the AC grid by pushing the plug into the outlet. AC motor then started acting as a generator, delivering useful power to load. Its speed would immediately drop to little above 1800 RPM synchronous speed, and remained stable thereafter. Direct connection was safely tested up to 4500 RPM. System speed before AC grid was connected was entirely dependent on DC motor running freely open-loop, rotating only AC motor's rotor and its own armature (rotor).

Table on this page indicates that speed of the system varies very little for a great increase in driving power required. Above 1800 RPM synchronous speed active power delivered (and taken from prime mover) increases very quickly. Test data:

DC motor: 12 V, 8 A (full load current estimate) AC motor running as generator: P=0.05 HP (37.3 W) V=115 V I=1.6 A Rated speed=1725 RPM Calculated values for AC motor: S=184 VA Q=180 VAR Current lag angle=78 degrees PF=0.202 Required capacitance for Q=180 VAR is 33.2 microfarads

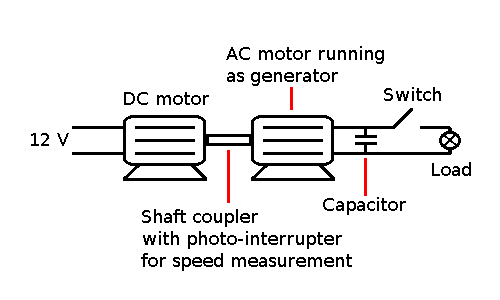

In this setup operating as standalone generator, reactive power is provided by capacitor connected between the motor terminals. Therefore, grid connection is NOT used, but AC is still produced. We will presently examine small asynchronous (squirrel-cage) motor as an AC generator without connection to alternating current grid, using capacitors to provide reactive power. Test setup connections:

Picture of the test setup.

Video taken during testing is linked below. DC motor is turned on, turning the shaft of the AC motor/generator. Lightbulb (connected to the AC motor/gen only) is then screwed in and it lights up. This causes the motor to slow down (listen carefully). When bulb is screwed out (electrical load on AC generator is reduced), motor speeds up. Testing video on YouTube:

DC motor was used to drive the AC asynchronous (squirrel-cage) motor. When speed in range of 1500-3500 RPM was reached, AC motor with attached capacitor would build up it's terminal voltage to around 120 V in 1-2 seconds. When this happened, switch to load (lightbulb) was closed and AC motor started acting as a generator, delivering useful power to load. Speed before switch was closed was entirely dependent on capacitor, DC motor running freely open-loop.

When AC generator was overloaded, voltage would drop to 65-100 V range. If overloaded even more, it would drop-out of generation to 0 V. After a drop-out AC generator would not generate again until a brief current flash was applied to its windings. Current flash was done by connecting a 12 V DC source to main AC motor winding for one second. This will re-establish some remanent magnetism in the iron core, which will be enough to initiate oscillation when motor is required to generate again. It is recommended to disconnect the load prior to generator turn-off, to prevent this drop-out. While this is not necessary for small loads, it will ensure reliable operation.

Table below indicates that wide range of capacitance will produce usable voltages in 120 V range, at frequencies close to 60 Hz. Since both motor and generator are small and inefficient types, maximum usable load (100-130 V, 50-70 Hz range) was only 10-13 W (30-35%) of motor rated mechanical power. However, other sources have reported 60-90 % usable resistive load for larger motors. Test results without grid connection, using capacitors for reactive power:

It was shown that even very small and inefficient squirrel-cage motor can work as a generator. It was shown that with wide range of speed and capacitance generator will still generate voltage and power. It was shown that asynchronous motors can be used as generators with or without grid connections. Since AC motors are generally inexpensive and more reliable than DC motors (no brushes), they can be used for remote site electricity generation. By having a control system with switchable capacitors for different loads, frequency and voltage could be adjusted to be within required range. Best use for squirrel-cage generator would be in micro-hydro electricity generation, where driving speed changes are limited. It is used as such in many installations around the world. Most of those are connected to the grid, and hence require no capacitors for magnetizing current (reactive power), since reactive power is taken from the AC grid. For wind turbines, it is more difficult to get the system to work majority of the time. However, many commercial wind turbines use induction motors as generators, and special control systems to keep the speed nearly constant.

Electrical Machines, Drives, and Power Systems, 4th edition, Theodore Wildi, Prentice Hall, ISBN 0-13-082460-7, pages 312 to 314.